Keeping the V8 Alive

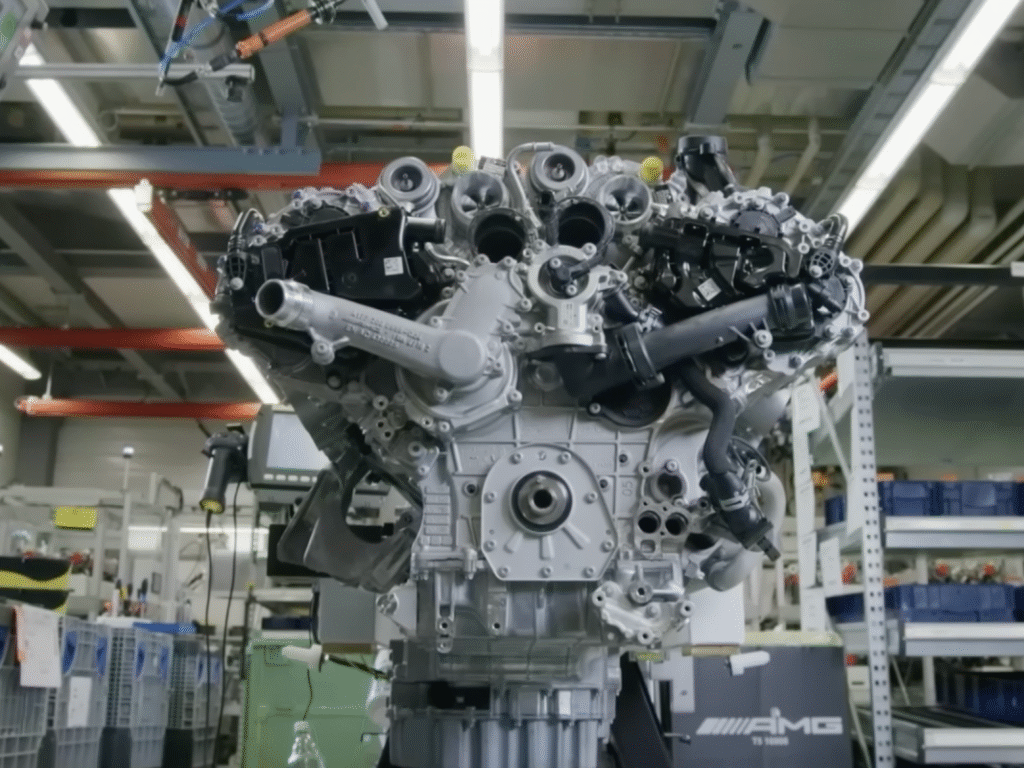

Despite the broader industry shift toward electrification, Mercedes-AMG intends to retain a V8 engine in its lineup, with a comprehensively reworked version scheduled to debut in 2027. AMG’s V8 powerplants are still hand-assembled at the brand’s headquarters in Affalterbach, Germany, and a recent video from FRAME provides a behind-the-scenes look at how these high-performance engines are brought to life.

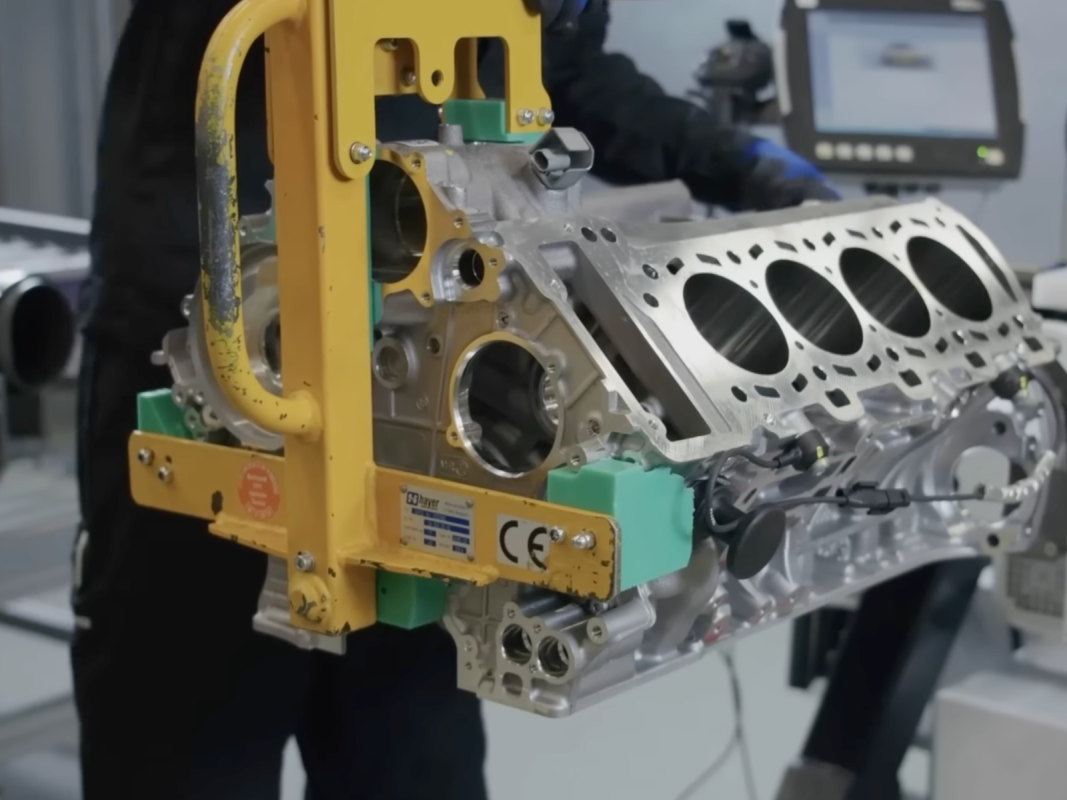

The engine features cast-alloy blocks and cylinder heads, a configuration chosen to reduce overall weight while improving thermal efficiency. It is paired with twin turbochargers, with output levels varying depending on the specific application. This V8 architecture has been deployed across multiple performance-oriented models, including the Mercedes-AMG GT and even the Aston Martin Vantage.

Engine Assembly Process

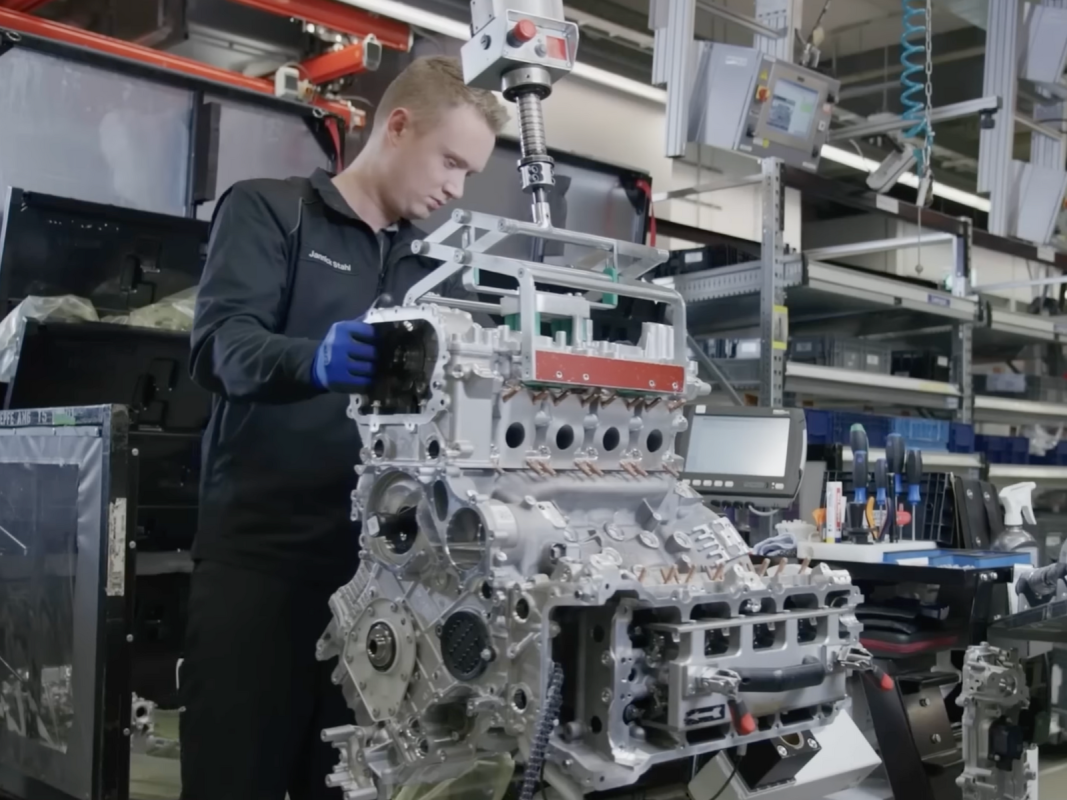

Established in 1976, the Mercedes-AMG production facility employs roughly 2,600 workers. During the assembly process, technicians rely on precision jigs to accurately position and secure locator pins on the engine block, which itself is mounted to a rotatable fixture. This setup allows for improved accessibility from multiple angles throughout the build process. Specialized equipment—including spring-assisted torque wrenches and overhead mechanized torque systems—is used to ensure that bolts are tightened precisely to factory-specified torque values.

After assembly is completed, the engines are moved to a dedicated testing workstation for operational evaluation. This includes both hot and cold testing cycles designed to confirm proper operation and consistency across a wide range of temperatures. Such validation is especially critical given the engine’s high-performance focus, as turbocharged configurations are particularly sensitive to temperature fluctuations that can affect efficiency and reliability.

To finalize installation, each engine is mounted into its respective vehicle using a three-point, rubber-isolated mounting system, a process commonly referred to as “marriage” within automotive manufacturing.

What’s Next for Mercedes-AMG

Looking ahead, Mercedes-AMG has confirmed that its next-generation V8 will be updated to meet more stringent emission standards. This development follows the brand’s controversial decision to replace its V8 engines with a hybridized turbocharged inline-four in models such as the C63 and GLC63. Although that electrified setup delivered a higher peak output of 671 horsepower, the move was met with resistance from enthusiasts. AMG CEO Michael Schiebe has since acknowledged that demand for V8-powered vehicles remains strong, particularly in the U.S. market.

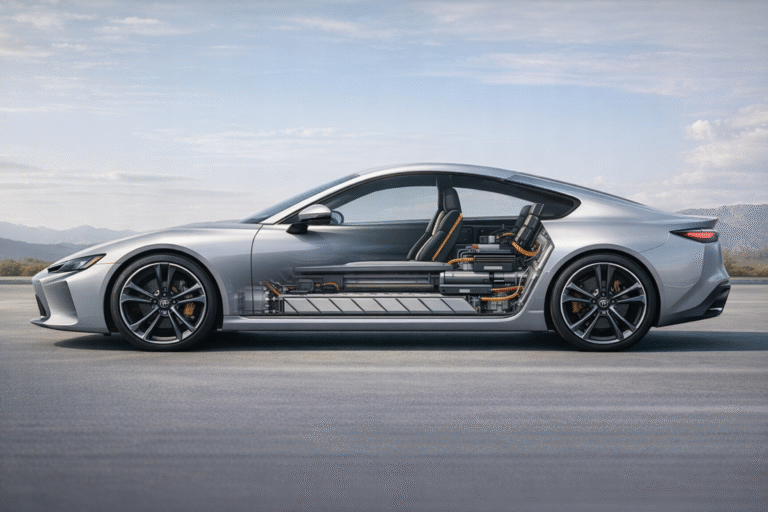

At the same time, Mercedes-AMG continues to expand its electrified lineup. The brand is preparing its first series-production model based on the AMG.EA high-performance electric architecture, which was previewed by the Concept AMG GT XX. That concept is claimed to produce up to 1,341 horsepower, with a production version expected to arrive later this year.