Chassis Evolution Through the Years

Car chassis design and construction are ever-evolving. From the widespread use of ladder frames in the ‘50s and ‘60s, to the almost universal shift to monocoque unibody construction in the ‘70s and ‘80s, the focus has constantly been on developing stiffer structures that resist flex. This direction of chassis development has been driven by the need to keep pace with the natural progression of automotive technology over the years: more powerful engines that increase drivetrain loads, radial tyres that offer high levels of lateral grip and torsional loads, and sportier cars that demand sharp and predictable handling at high speeds.

Honda

Why the Chassis Shouldn’t Flex

Many forces act on a vehicle’s structure: the weight of the engine and occupants, the torque being transferred to the wheels when accelerating, weight transfer and forward pitching when braking, and the lateral g-forces generated when going around a corner — all of these push, pull and twist the chassis in various directions.

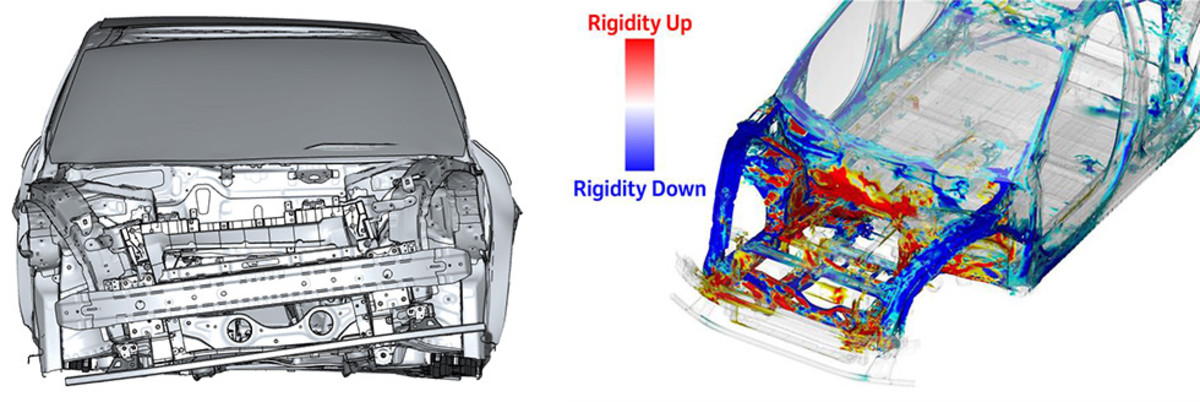

Logic dictates that the chassis should be robust enough to maintain its shape and structural integrity under all these forces, aiming to maintain ride quality and ensure safety, as well as provide consistent and predictable handling and steering performance. Well, Honda is about to flip this logic on its head. The Japanese manufacturer is exploring how strategically engineered compliance can actually unlock better handling, sharper steering feel, and a quieter, more comfortable ride, while also trimming weight and cost.

Honda

Honda’s Flexible Chassis

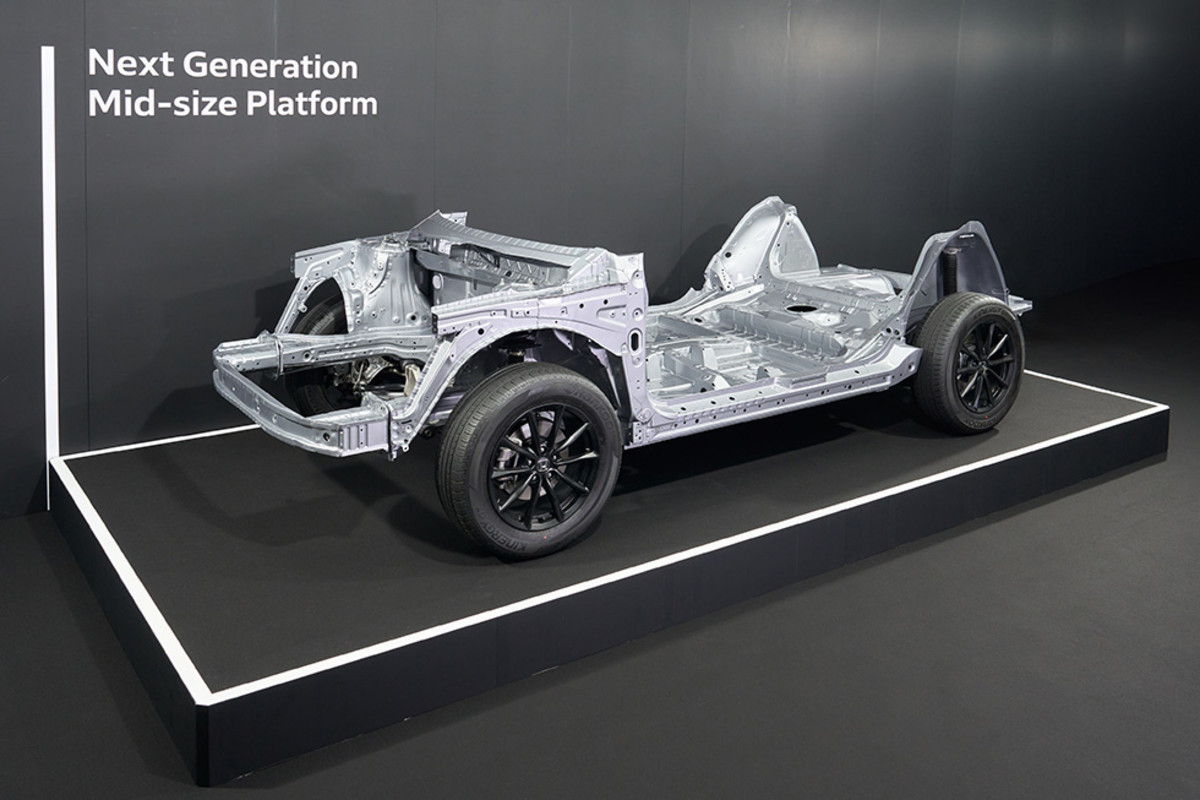

Honda recently announced the development of the next-generation mid-size vehicle platform that will underpin cars like the Civic, Pilot, Passport, CR-V, and Odyssey, as well as upcoming EV models such as the 0 Series and a production version of the Super-ONE prototype. The standout feature of this new platform is that rather than focusing on eliminating flex and building a frame that is as rigid as possible, Honda have opted to optimize the flex characteristics of the new platform to work in their favor.

Honda

How Does it Work?

The Japanese manufacturer has engineered a chassis that will deform in a predictable manner under load to enhance dynamic performance and driving stability, while also reducing vehicle weight. This out-of-the-box approach allows part of the front structure to bend and twist under excessive cornering forces, in a manner that pushes the outer wheels into the road surface rather that towards the outside of the corner.

Honda

More Grip; Better Feel

Honda’s calculated chassis flex is designed to improve handling and provide the driver with more information through the steering wheel, while also enhancing comfort by absorbing bumps and surface irregularities without transferring them into the cabin.

The core principle behind Honda’s approach revolves around reshaping the load paths through the chassis and allowing them to work with the vehicle’s suspension rather than against it. Their engineers claim that their new platform offers a front end that feels more connected and settled, while resisting the understeer that creeps into front-heavy vehicles.

Honda

Modular, Lighter, and Cheaper

Honda’s new mid-size vehicle platform features a modular architecture with fixed hard points at the front and rear, enabling easy sharing of components across different vehicle sizes. Targeting over 60 percent parts commonality across various models, this approach is sure to speed up development. Honda also claim that their new platform will be around 200 lbs lighter and roughly 10 percent cheaper to build than the existing architecture.

Honda

Arriving in 2027 to Challenge Industry Beliefs

The first production models using this new platform are scheduled to arrive in 2027. If Honda’s flexible chassis design proves itself, the industry may need to rethink the long-held belief that chassis rigidity is a universal virtue. Honda’s innovative approach is a reminder that the smartest engineering comes not from resisting every force, but from shaping how those forces move through a structure, and that the smartest chassis isn’t simply the stiffest one, it’s the one that knows where to bend.