Power Density

It’s not unusual for modern performance cars to make over 200 hp/liter, with ultra-exclusive supercars even breaching the 300 hp/liter mark. Of course, these figures are achieved by forcing massive amounts of air into the cylinders at each intake stroke, with electric motors picking up the slack. Back in the ‘90s, however, when turbocharged or supercharged engines were considered too heavy, complex, fragile, high-maintenance, and unpredictable to generate mainstream appeal, a revvy, naturally-aspirated motor with a specific output of over 100 hp/liter was special.

Honda was, at the time, known for technological innovation, precision engineering, racing excellence, and exceptional reliability, and was working on a car to commemorate the company’s 50th anniversary. It had to be special, embodying the brand’s heritage and quest for engineering excellence, but also be attainable and fun. Honda engineers Shigeru Uehara and Yoshiaki Akimoto were given the task of creating a fast, two-seater roadster, and a bespoke engine to go with this new sportscar. In 1999, they delivered the S2000 and the groundbreaking F20C — a tiny four-cylinder motor that made more power per liter than the naturally-aspirated V10 and V12 engines built by Lamborghini and Ferrari.

Honda

Pushing Boundaries

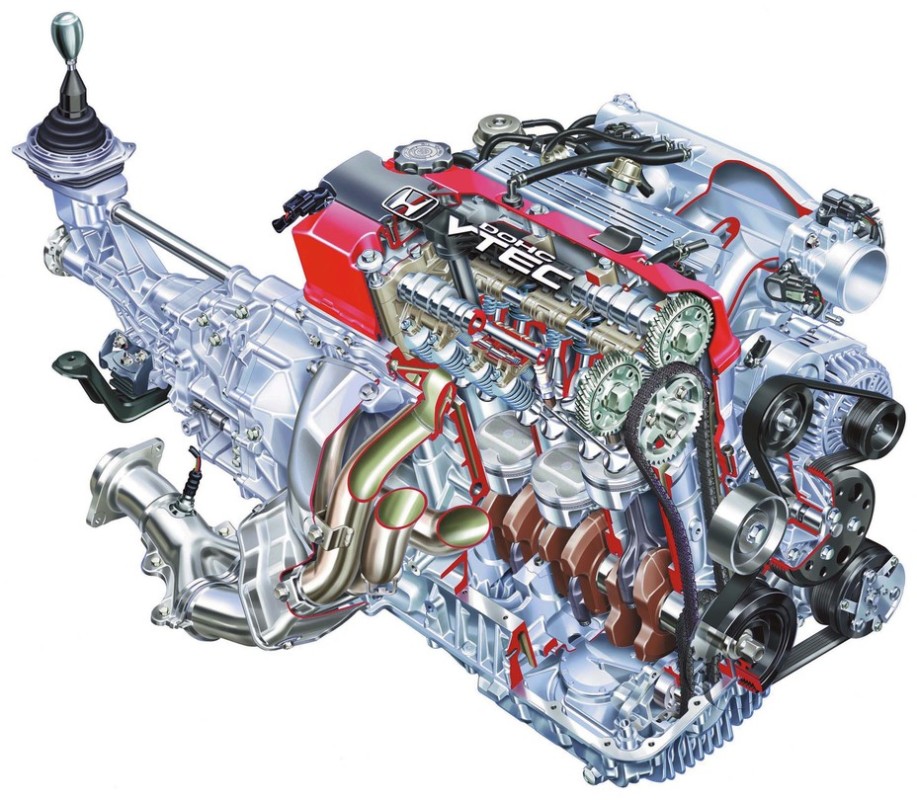

The brief seemed simple at first — create a high-revving, compact, power-dense, naturally-aspirated, four-cylinder engine for a lightweight, rear-wheel-drive roadster. Honda was well known for their small, rev-happy motors, so this should have been simple enough; however, the brand’s existing B series engines were getting quite long in the tooth, and the K series hadn’t been created yet. Also, both these engines were designed to be mounted transversely to drive the front wheels, while the brief called for a longitudinal front-mid-mounted engine driving the rear wheels via a six-speed manual transmission.

The engineers had to start from the ground up, occasionally dipping into Honda’s motorsports expertise and experience to create the F20C from scratch. The result was the most power-dense naturally-aspirated engine ever created — a 1,997-cc four-cylinder motor that screamed all the way to 9,000 rpm and put out 247 hp for a record-setting specific output of 123.5 hp/liter. The F20C held this record for over a decade, until it was finally dethroned by the Ferrari 458 Italia’s V8.

The Challenge

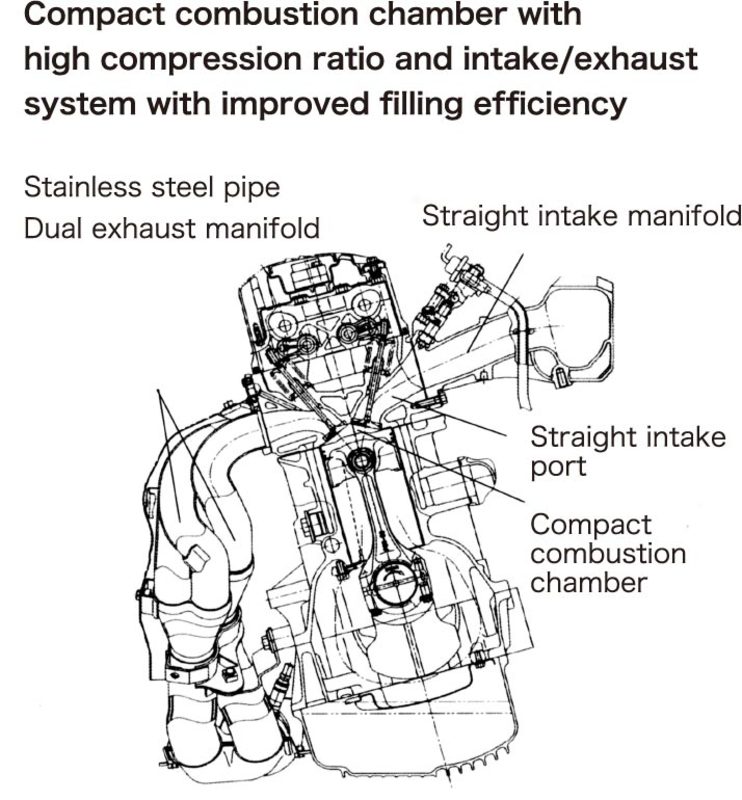

To build an engine that could reliably spin at speeds that would cause lesser motors to destroy themselves, Honda’s engineers had to focus on optimising cylinder breathing, reducing internal friction, and refining combustion chamber design. What they achieved ultimately set new standards for what was thought possible from a 2.0-liter naturally-aspirated engine.

Ambition meets Precision

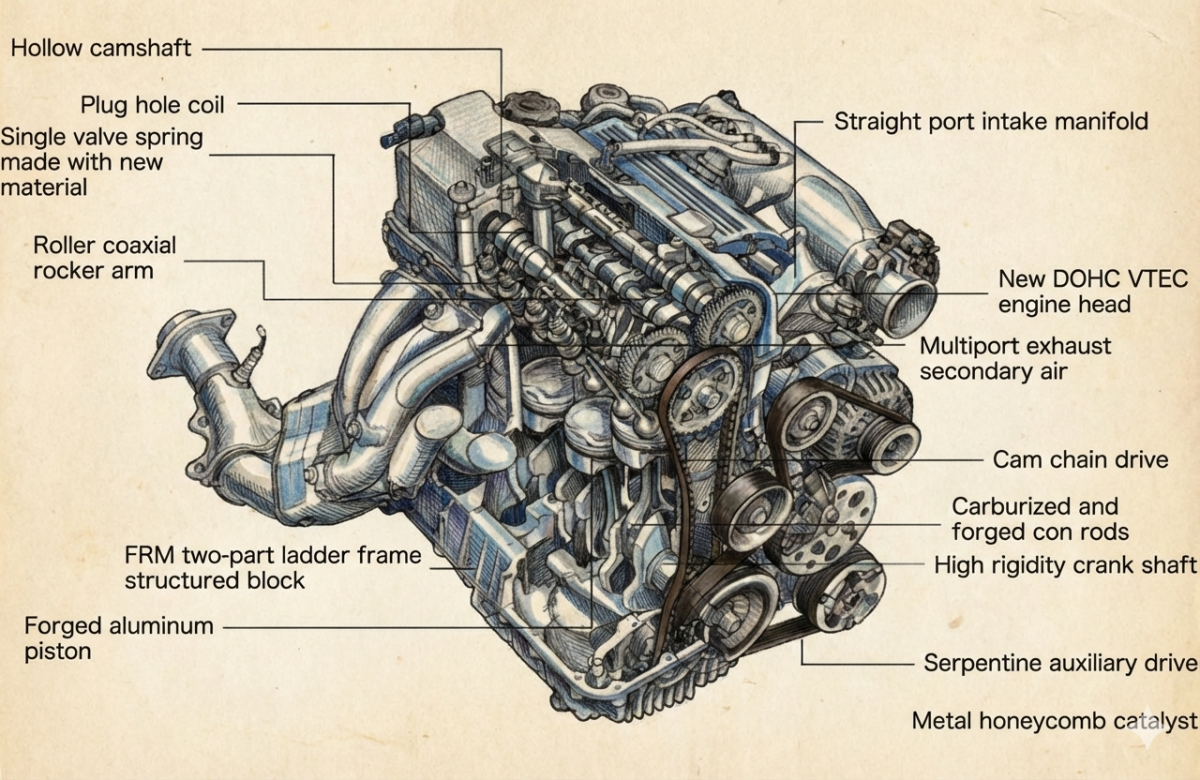

The block was aluminum with fiber-reinforced cylinder liners that allowed for thinner cylinder walls to keep weight low while retaining strength and aiding in heat dissipation. Pistons were forged aluminum, the first for a Honda road car. They needed to be strong and lightweight, as they would see a mean piston speed of 25.2 m/sec at redline, the highest for a production car at the time. The pistons were coated with molybdenum disulfide to minimize friction, while the forged steel crankshaft was supported by five main bearings, rather than the customary three, to boost rigidity.

The Valvetrain

Up top, valves were as slim and light as possible while still being strong enough to withstand the stresses of high-rpm operation. They were operated by a pair of hollow camshafts and high-strength valve springs that were developed specifically for the F20C using tech from Honda’s racing programs. Of course, the valvetrain was equipped with VTEC, set up to kick in at 5,850 rpm and incorporating innovative roller coaxial rocker arms to reduce valvetrain friction. In fact, Honda still considers the F20C the pinnacle of their variable valve tech, and refers to it as the ultimate naturally-aspirated VTEC engine.

Intake and Exhaust Efficiency

For an engine to run at high rpm, it needs to be able to breathe freely, and the F20C’s intake and exhaust plumbing was designed to do just that. An intake manifold with absolutely no bends provided a straight shot to 36-mm intake ports, while burnt gases were evacuated via 21-mm exhaust ports and a steel 4-3-2 exhaust manifold.

Strength and Reliability

When the Honda S2000 debuted in mid 1999, it stunned the industry with its 9,000 rpm redline and record-setting specific output. To many, the screaming engine seemed less like a production motor and more like something pulled from a racetrack paddock. But race engines get inspected and rebuilt after every few hours of operation, while the F20C was expected to be durable and reliable, even after thousands of miles of high-rpm operation. This is where Honda’s precise machining and meticulous quality control came into play. The engine soon proved its robustness, with owners realising that they could enjoy this little motor’s high-rpm thrills for years, without having to worry about it falling apart.

Honda

A Lasting Legacy

The F20C cemented Honda’s reputation as a master of small, naturally-aspirated performance engines at a time when the industry was beginning to pivot towards turbocharging. It was one last hurrah for drivers and enthusiasts who valued the high revs, precise throttle response, and mechanical purity that only a free-breathing engine can provide. It’s no wonder then that even a quarter of a century later, the F20C is still considered one of the greatest four-cylinder engines ever built.