The EV Packaging Problem Nobody Loves Talking About

Electric vehicles (EVs) address plenty of challenges, but maximizing interior space isn’t always one of them. Today’s EV batteries are large, heavy units mounted under the floor, and that extra thickness comes with tradeoffs. Higher floors mean seating positions shift, and designers often have to make tough choices about rooflines, legroom, or the car’s overall shape. Some EVs end up looking taller than necessary, while others sacrifice cabin comfort just to keep the exterior profile in line.

This problem stands out most in smaller EVs and family cars, where any bit of interior space counts. Even with smart packaging, there’s only so much room to work with when the battery sets the floor height. That’s the challenge Toyota seems to be tackling in a new patent, which focuses less on battery chemistry and more on how the components are arranged under the car.

As always, it’s worth noting that patents and trademarks are not guarantees of production. Automakers file these documents to protect ideas, explore concepts, or future-proof engineering directions that may never reach the showroom.

USPTO

A Different Way to Arrange the EV “Skateboard”

Filed to the US Patent and Trademark Office in June 2025 (look it up using patent no. 20260021715) and published just last week, Toyota’s filing outlines an alternative way to package an EV’s battery and major electrical components.

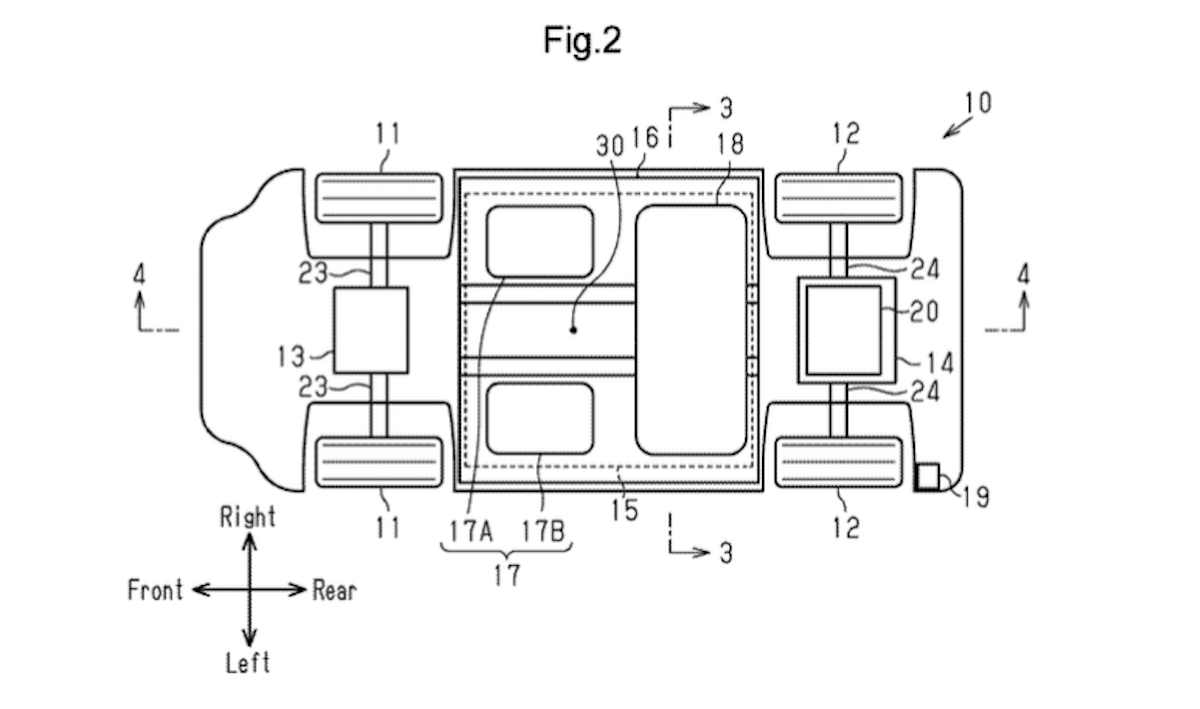

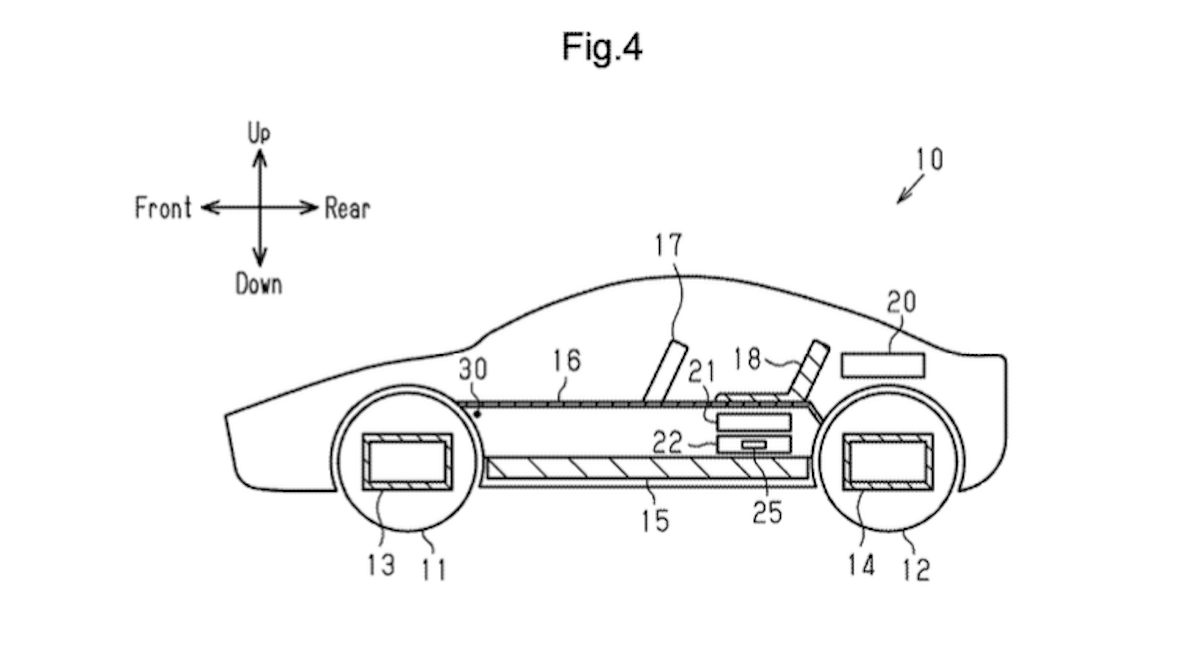

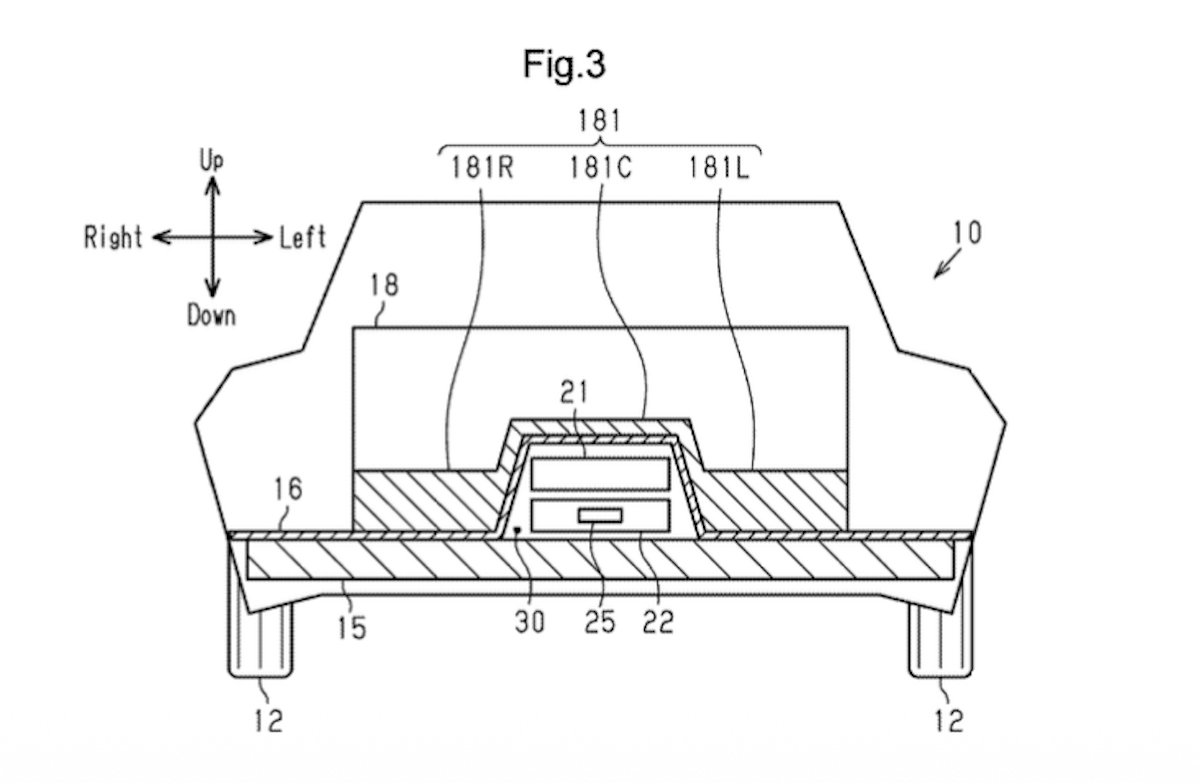

Rather than stacking everything in one thick layer, Toyota’s idea is to spread out key components in a more layered setup. The battery still sits under the floor, but electronics like power control units and junction boxes are moved so they aren’t all piled up in the same spot. The goal is to cut down on bulk by changing how things are arranged, not by making the battery itself thinner.

The patent diagrams show the battery doing double duty, working as both an energy source and a structural part that shields sensitive electronics. By keeping cable runs short and grouping components closer together, Toyota could save space and boost efficiency, all without changing the battery’s chemistry.

USPTO

Why This Matters If It Ever Reaches Production

If this kind of layout reaches production, the benefits for buyers would be clear. A thinner floor could allow for lower seats, more headroom, or extra legroom without making the car any bigger. Designers would also have more flexibility to shape EVs that look sleeker, instead of relying on tall, upright bodies to hide thick underfloors.

For family EVs, this could mean more usable space in the second row or more flexible cargo layouts. For smaller models, it could bring back proportions that look more like classic hatchbacks and sedans, instead of defaulting to tall crossovers.

Moreover, a more flexible underfloor setup could be used through different body styles, drivetrains, and markets without having to start over each time. It’s not clear whether this exact idea will make it to production, but it shows Toyota is focused on practical ways to improve the use of space.

USPTO